Expertise.

Customization.

Cutting-edge technology

Attention to detail.

Empowering Automotive and Medical Component Manufacturing & Decoration

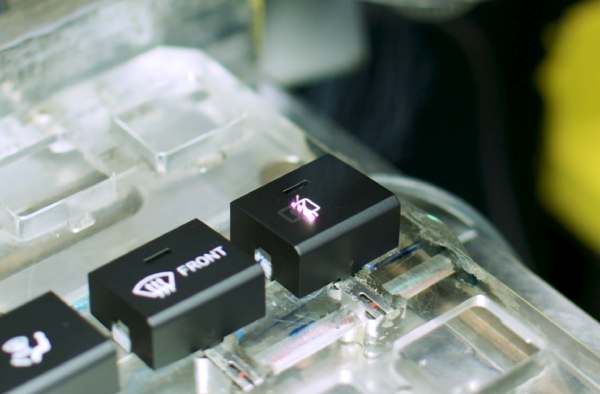

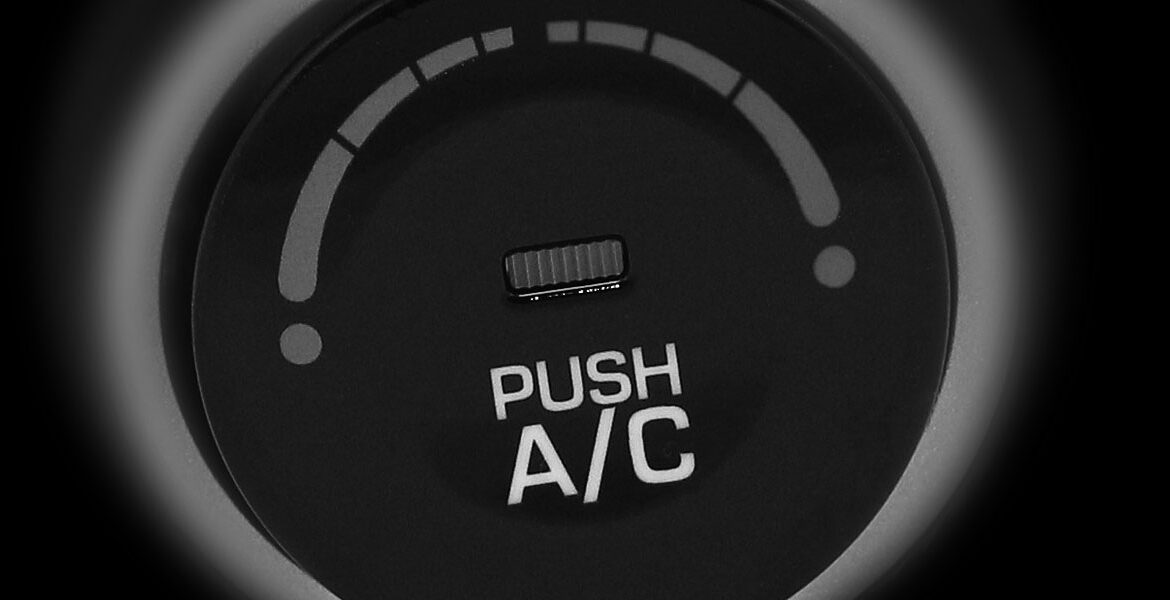

Solution provider

for HMIs

and

E-Mobility

applications.

Empowering Automotive Component Manufacturing & Decoration

Innovative optical

and haptic technologies

deliver

impressive

results.

Empowering Automotive Component Manufacturing & Decoration

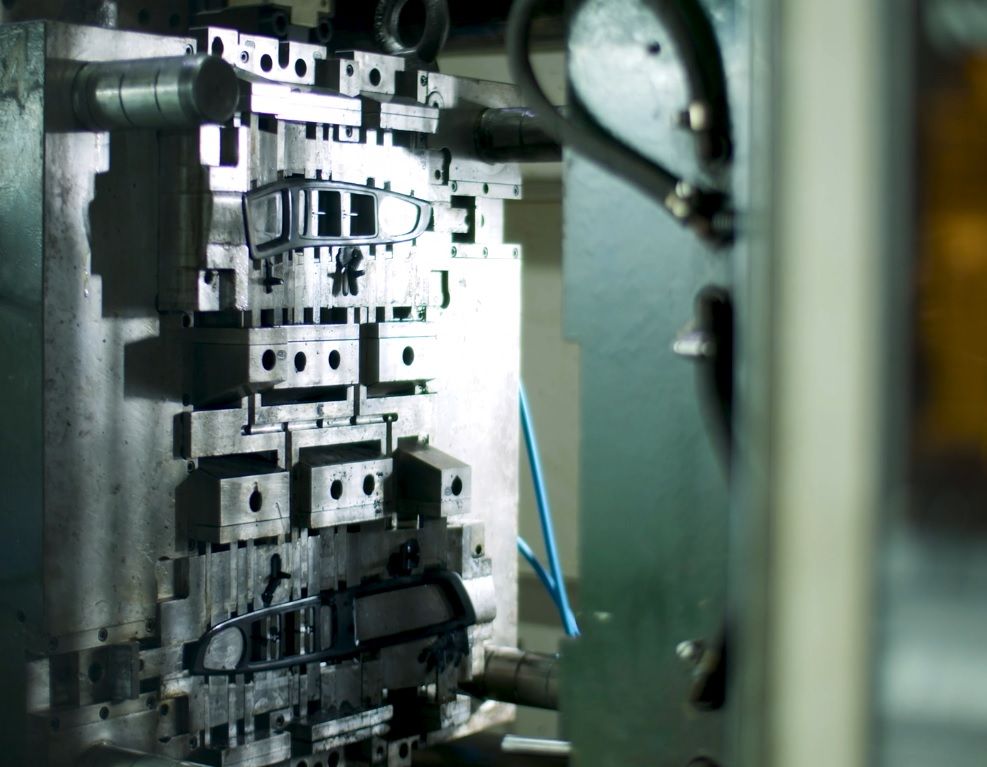

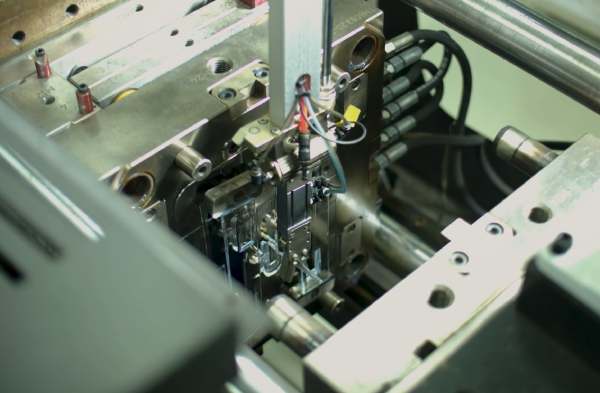

Production facilities,

to ensure the highest

quality and productivity

of the product.

Empowering Automotive Component Manufacturing & Decoration

Medical

Component and

Device

Manufacturing

Precision Medical Device Molding From Concept to Compliance (Made in India)