Injection Molding

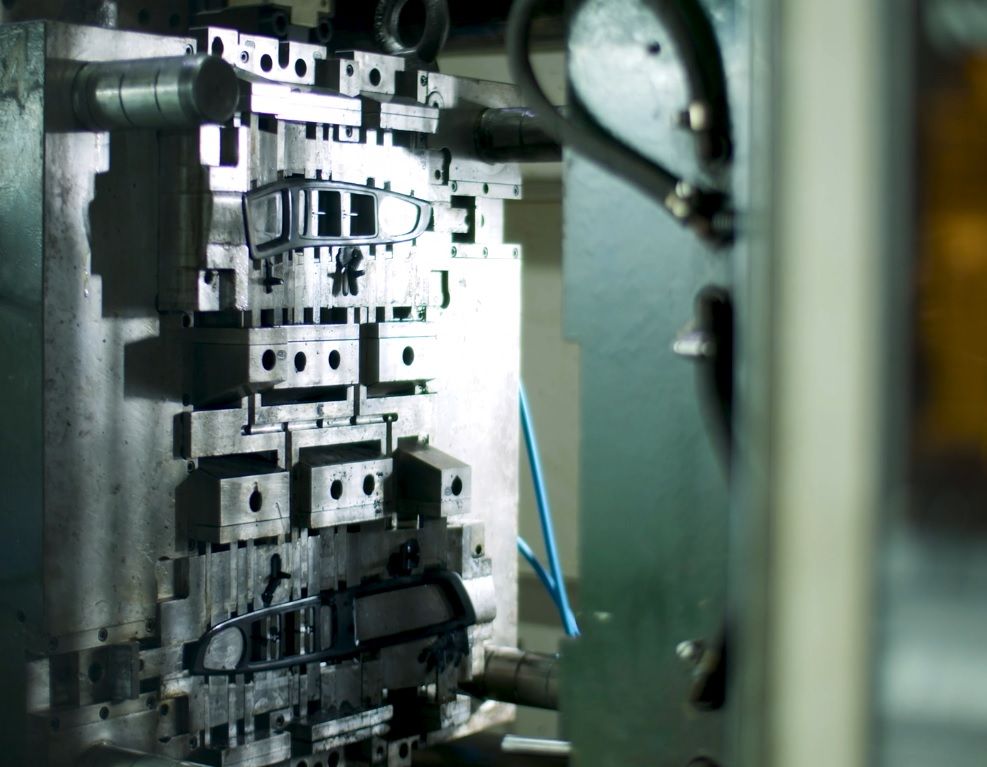

Injection molding plays a crucial role in the automotive industry. It is a manufacturing process used to produce a wide range of automotive components and parts, especially those made from plastic or polymer materials. This method offers various advantages such as cost-effectiveness, high production rates, design flexibility, and the ability to create complex shapes with precision.

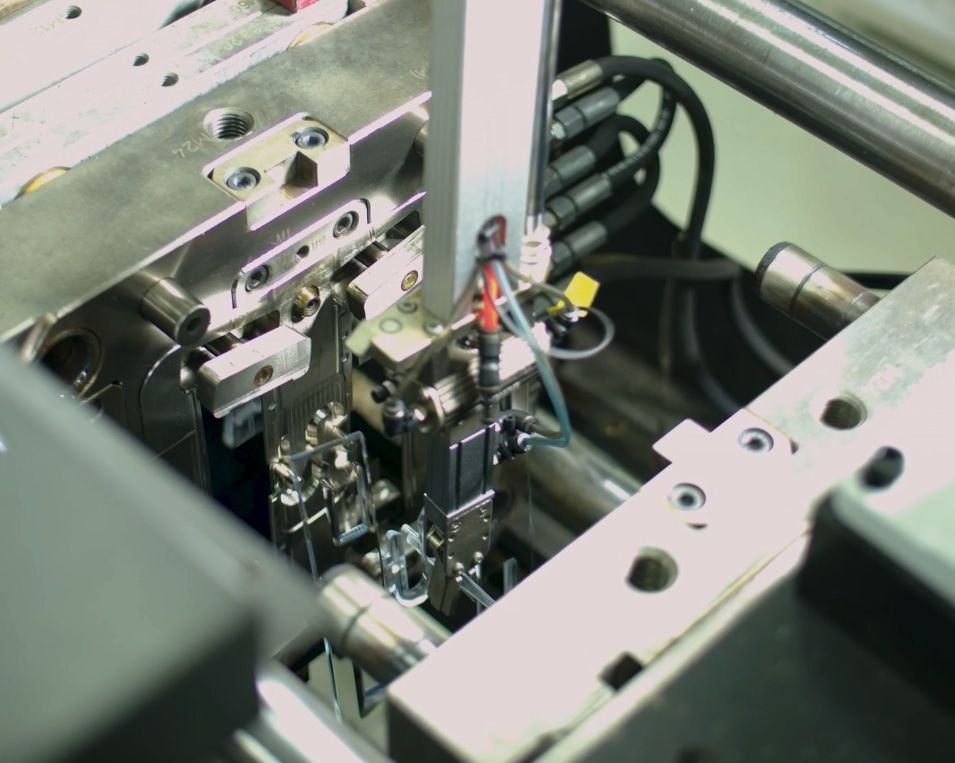

Spinks Softech is setting new benchmark for injection modling in automotive industry. We use only world class machines from Europe for precision molding requirements. “End to End” Solutions from Injection molding to spray coating services are available at Spinks.